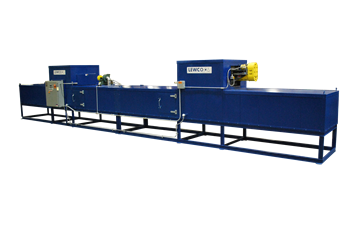

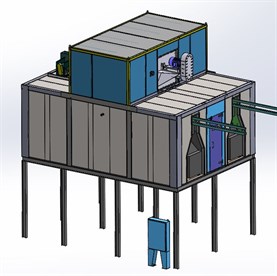

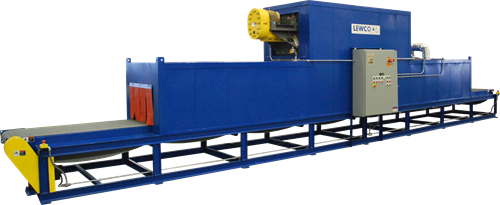

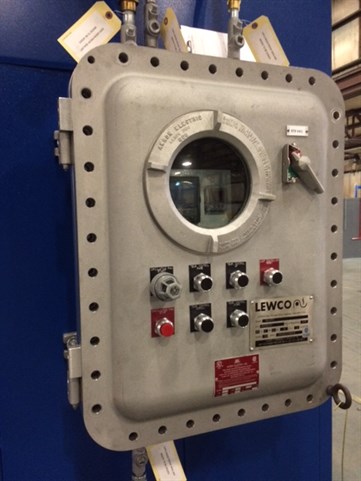

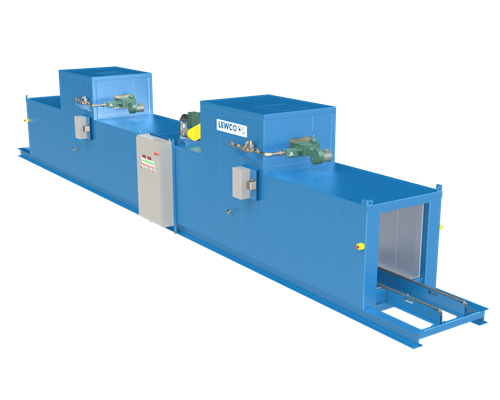

Custom Hot Box Provides Safe Heating

LEWCO, Inc. recently manufactured a custom drum heater for a large government contractor. The hot box is steam heated and rated for a maximum operating temperature of 300°F. The oven is designed to heat (8) 55-gallon drums and is equipped with a self-acting controller that has an operating temperature range of 125°F – 212°F. Installation …