Custom Engineered Oven for A Major Aircraft Parts Manufacturer

This customer required vacuum composite curing of aircraft parts at a maximum temperature of 500°F. The oven is specified to be NFPA 86 Class A and is installed indoors in an industrial manufacturing environment.

Key customer specifications include:

- Heating Medium: Natural Gas

- Capacity: (4) zones at 700,000 BTU’s each

- Workspace Volume: 1,120 cubic feet per zone

- Center Guillotine Doors divide the chamber

- Automatic, actuated safety pins help protect against door failure

- Construction: 20 gauge aluminized steel with 12 gauge carbon steel, plate floor

- (48) ½” NPT vacuum ports with automatic solenoid valves and dial-type gauges on main headers

- Variable vacuum pressure

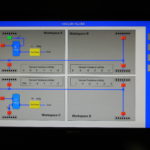

- Desktop PC, touchscreen control center provides the operator with all control of oven functions and data logging from the PC.