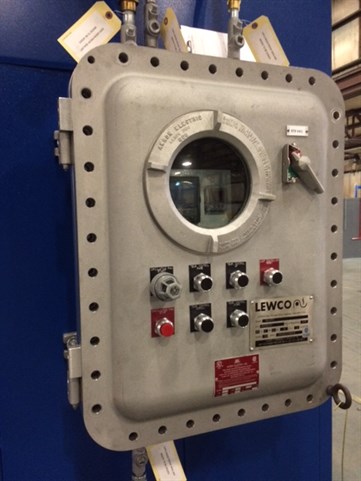

Revitalizing 22-Year-Old Cabinet Oven: A LEWCO Success Story

When a long-time customer asks if you can refurbish their 22-year-old cabinet oven, some may be hesitant to say yes… but not LEWCO. The oven was originally manufactured by LEWCO in 2002 under the Heat-Pro brand name. For its age, the oven was in solid shape with great bones, but it needed some TLC and …

Read More “Revitalizing 22-Year-Old Cabinet Oven: A LEWCO Success Story”