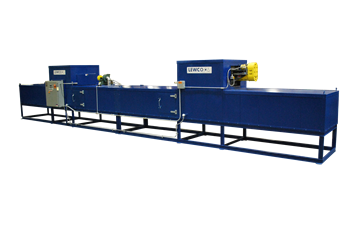

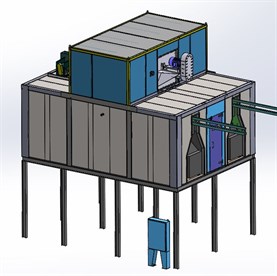

Custom Conveyor Oven? Trust the Experts at LEWCO

LEWCO, Inc. recently delivered a continuous process composite curing oven to a government contractor. The application is rotational curing of large composite mandrels in a continuous process. A critical design parameter was having the conveyor start and stop for indexing, while still maintaining rotation. While inside the oven, the mandrels will travel through two independently …

Read More “Custom Conveyor Oven? Trust the Experts at LEWCO”