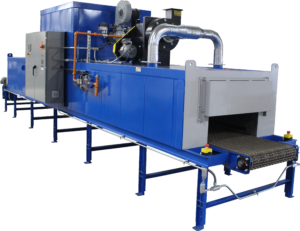

LEWCO Delivers 500°F Continuous Curing Oven

LEWCO, Inc. was recently chosen to design and develop a conveyor oven for a manufacturer of iron cookware. The oven, which is rated for a maximum operating temperature of 500°F, is used to cure a special coating at 475°F.

The oven features a single, direct-fired, natural gas heater-box with a capacity of 700,000 BTU’s/HR. The burner is configured for propane fuel to start but will convert to natural gas in the future. The oven is equipped with a 7,000 CFM circulation fan and a 750 CFM exhaust fan which include air proving circuits that are electrically interlocked with the heating circuit. The high-efficiency circulation fan and integral plenums deliver uniform vertical down airflow throughout the workspace.

Adjustable insulated panels are installed on the entrance and exit openings to minimize the air leakage into the rest of the plant. The oven is also supplied with an insulated access panel on side wall for easy access to the oven chamber for service and maintenance.

Controls include a Eurotherm temperature controller and redundant high-limit controller. A PLC is interfaced with a touchscreen HMI allowing the customer to easily control all oven and conveyor operations from one convenient interface. A variable speed drive is included and allows the conveyor speed to be adjusted from 1-3 feet per minute.

LEWCO was awarded this contract because our application engineers took the time to thoroughly understand the process and develop a cost-effective solution for the customer, says Lou Schaefer, Oven Sales Manager/ Sr. Applications Engineer. LEWCO did considerable amount of pre-sale testing to determine the best oven configuration and airflow to achieve the customer’s quality requirements.