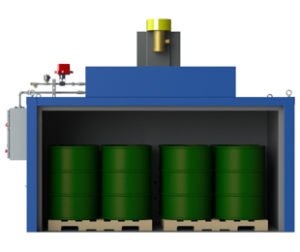

LEWCO High-Performance Drum Ovens provide 25% faster heat-up times and, by design, are safer than traditional Hot Boxes. The Low Profile design features a 12 gauge steel plate floor that allows for convenient loading with a pallet jack or drum dolly. As standard, High-Performance Ovens are designed and manufactured to meet the requirements of NFPA 86, Class B ovens. All models feature our signature all-welded steel, heavy-duty construction and simple, user-friendly controls. Each unit comes complete with a (3) year warranty and is fully assembled, wired, and tested prior to shipment.

Operating Temperature

125°F (52°C) to 300°F (150°C)

Note: Maximum achievable temperature is dependent on steam pressure

Capacity

(8) 55-gallon drums palletized

Heat Source & Capacity

Saturated steam, 20-125 PSIG

- Heat Exchanger: maximum 182,000 BTU’s per hour @ 75 PSIG.

- Hot oil and hot water (20-100 PSIG) also available.

- Optional low-pressure valve for minimum of 10 PSIG steam.

Circulation Fan

2,000 CFM, TEFC motor

Optional: Explosion-proof motor

Electrical Requirements

Voltage: 480/3/60. Please consult factory for additional voltage options.

Disconnect Size: 30 AMPS

Additional Options:

- Exhaust fan: 100 CFM, TEFC motor

- NFPA 86 Class A rating

- Stainless steel construction

Shipping & Installation

Ships completely assembled for easy installation. Simply connect utilities and your oven is ready for use!

Control System

LEWCO’s standard control package includes a single set-point process temperature controller and redundant high-limit controller. Circulation fan(s) and exhaust fan(s) include air proving circuits that are electrically interlocked with the heating circuit. All controls are housed in a NEMA 12 enclosure employing a full voltage lockable disconnect switch. Controls are wired to NFPA 70 and 79 electrical standards in our own UL508A certified panel shop. These models meet the requirements of NFPA 86, Class B ovens Independent third party inspections available.

Optional:

- NEMA 7 explosion-proof electrical

- Batch Timer: Infinitely adjustable up to 100 hours; includes illuminated On/ Off switch to indicate timed operation and audible alarm when time has elapsed.

- Data Logger: Multiple input digital data logger continuously records temperature and other process data. Allows downloading of digital data files through USB or Ethernet connection. Data can also be viewed on a full color display or on a web server when connected to a network.

- Door Switch: Automatically disables heat when door is opened.

- Ramp/ Soak Controller: Programmable ramp/ soak temperature controller with capability to store different recipes with multiple segments.

- Zero Speed Switch for Fans: Minimizes nuisance tripping associated with standard airflow switch(s).

Standard drum oven construction includes an all welded 1/8″ steel shell with 4″ x 6# mineral wool insulation. Heat loss is minimized by a proprietary wall design featuring a welded inner shell and a completely isolated outer frame and covers. This model features top-mounted lifting eyes for easy installation and transportation.

Workspace Dimensions

108″ W x 55″ D x 55″ H

Doors

Heavy-duty doors with strap hinges, 2-point latch system, and high-temperature gaskets create a tight seal for efficient heating.

Finish

- Standard: Blue or gray alkyd enamel

- Optional: Premium finish for corrosive environments

- Elevated Temperature Storage Ovens: designed to maintain materials at a consistently high temperature for extended periods to preserve or hold materials at an elevated temperature preventing degradation or maintain specific conditions for quality control, efficiency, and safety.

- Industrial Melting Ovens: designed to heat solid materials to their melting point. This process is crucial for many manufacturing applications.

- Viscosity Reduction Ovens: designed to lower the viscosity of liquids, like heavy oils, waxes, plastics, and other materials with carefully controlled heating. These ovens make materials easier to pump, process, and handle, significantly improving efficiency.

LEWCO High-Performance Drum Ovens are designed and manufactured to industry standards. Our engineers stay current with the latest revisions to these standards. If there is a specific industry standard or code compliance that you require for your process heating application, please contact one of our highly knowledgeable Applications Engineers to learn how LEWCO can help!

As standard, High-Performance Ovens are designed and manufactured to meet the requirements of NFPA 86, Class B ovens. This model is not suitable for applications involving the off-gassing of flammable volatiles, or for installation in electrically hazardous locations. Consult factory for non-standard features required for compliance with NFPA 86, Class A ovens.

About NFPA 86

The National Fire Protection Association’s standard, NFPA 86, documents the guidelines for the safe operation of industrial ovens and furnaces. Oven and furnaces in which flammable volatiles or combustible materials are present in the work space are classified by NFPA 86 as “Class A.” Similarly, ovens and furnaces in which no flammable volatiles or combustible materials are present are classified as “Class B.” Due to the risk of fire or explosion, NFPA 86 requires specific safety equipment for all Class A ovens and furnaces.

- Powered exhaust of capacity determined by maximum solvent loading.

- Explosion relief of adequate area determined by oven or furnace workspace volume.

Industry Standards