LEWCO Designs Cell for Curing 3D Printed Parts

Three-Dimensional (3D) printing is rapidly becoming a popular method of manufacturing. One significant benefit of 3D printing is it allows companies to quickly build complex parts in a short period of time. LEWCO recently provided a process heating cell equipped with a cabinet style batch oven and automated material handling system. The oven is used to cure metal 3D printed parts at a maximum temperature of 500°F.

The manufacturing process begins with the customer’s part being printed in a customer supplied printing tote. From there the tote is sent to the oven where it is cured at temperature for up to a couple of days. The tote then travels to the de-powder station where the excess powder is removed. Finally, the tote is sent to the storage station where the part is removed.

The manufacturing process begins with the customer’s part being printed in a customer supplied printing tote. From there the tote is sent to the oven where it is cured at temperature for up to a couple of days. The tote then travels to the de-powder station where the excess powder is removed. Finally, the tote is sent to the storage station where the part is removed.

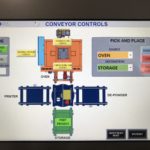

The batch oven, which features a workspace of 48”W x 36”D x 36”H, is manufactured and designed to NFPA 86 “Class A” standards. The oven is supplied with a top mounter heater-box with 108 kW heat input and a 1,700 CFM high-efficiency circulation fan delivering dual airflow to the workspace. The oven is equipped with 500 CFM exhaust fan to remove volatiles from the workspace and a LEL monitor to monitor the volatile level in the oven to ensure safe operating conditions. The interconnecting conveyors include a centrally located turntable with dual strand chain conveyor attached on top. Conveyors are designed to move a 4,800 LBS part. The turntable allows the tote to be sent to four different stations within the cell.

Controls include a touchscreen HMI interfaced with a PLC to allow the customer to easily control oven and conveyor operations from one convenient interface. Control functions include the ability to create, edit, and save multiple ramp/ soak recipes, control oven and conveyor operations, check oven status, and monitor, record, and retrieve process data.