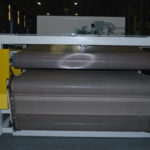

Conveyor Oven for Mattress Foam Manufacturer

LEWCO designed and manufactured a direct fired natural gas continuous process conveyor oven for a leading manufacturer of mattress foam. The oven operates close to 500°F and is used to cure a continuous web of foam coming off an adjacent mill. The foam can vary in width and thickness at a maximum of 90” wide x 8” thick.

The customer had several important design specifications to comply. The first was uniform airflow blowing vertically up through the material. The uniform hot air flow is critical to the quality of their product. A second important feature required a compression conveyor at the exit end of the oven. This conveyor is mounted directly over the main conveyor and sets the final thickness of the foam as it exits the oven. The compression conveyor can be raised and lowered from the control panel to produce ¼” to 8” thick foam. The conveyor is mounted upside down and the belt must have zero sag. A special bi-metal mesh belt with a magnetic slider bed was used to accomplish the zero sag requirement

Another unique design feature of the compression conveyor is the drive set-up. LEWCO’s engineering team developed a self-tensioning chain drive system that uses (1) motor/ gearbox to drive both lower and upper belts, while still allowing height adjustment on the compression conveyor.

One problem the customer has experienced with other conveyor ovens was conveyor belt life and tracking. LEWCO’s engineers solved this by attaching the belt to roller chains on both sides. The conveyor belt is driven and tracked by the chains, instead of the fiberglass mesh and pulleys. This helps to extend the belt life and tracking.

Basic Design Details

- Utility: Electric, 480/3/60; Natural Gas

- Maximum Temp: 500°F

- Heat Capacity: 700,000 BTUH

- Work-space Dimensions: 96” wide x 240” deep x 15” tall

- Airflow Pattern: Vertical Up

- Circulating Blower: 8,000 CFM

- Controls: Allen-Bradley PLC with touchscreen Panelview HMI