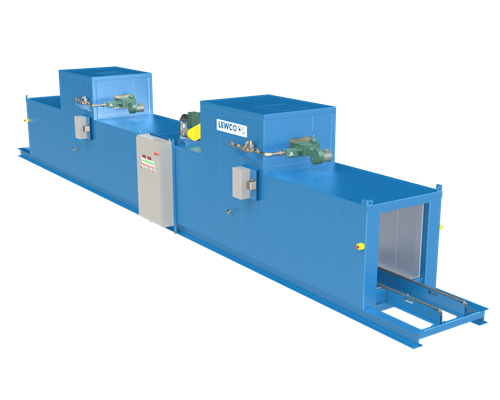

Custom Annealing Oven

LEWCO, Inc. manufactured six custom annealing ovens for a large tier-one automotive supplier located in northern Ohio. The ovens are used for annealing plastic taillight assemblies after a welding process. The process relieves stresses created during welding to facilitate easier assembly in the vehicle without cracking or clouding of the lens. The annealing process requires …