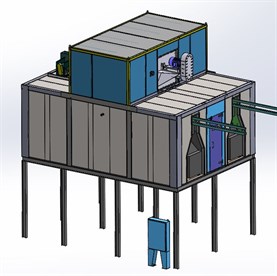

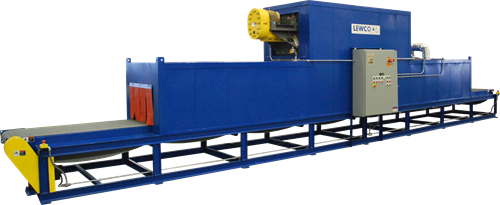

Field Assembled Conveyor Oven for Drying

LEWCO, Inc. recently was awarded a contract to design, fabricate and install a custom field assembled conveyor oven for drying a proprietary preservation coating. Due to the overall size of the oven along with the requirement to install on an existing elevated platform this project will be a field assembly design. This oven is required …