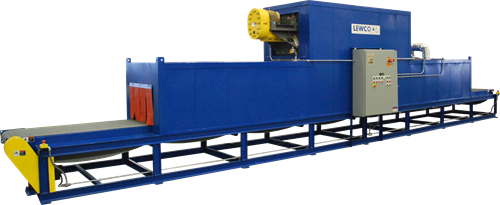

Drum Heating Cabinet with Vertical Lift Door

LEWCO recently completed a custom drum heating cabinet for a repeat customer in Thailand. The customer, a large petrochemical manufacturer, needed another drum heating cabinet in order to keep up with growing production requirements. LEWCO was selected for the job due to the customer’s high level of satisfaction with their first unit, which was purchased …