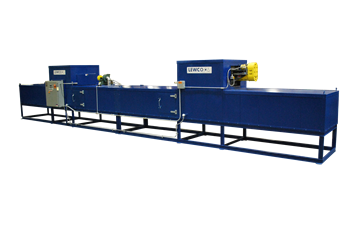

Custom Heating Cells Increase Production

When it comes to integrating material handling with process heating applications, LEWCO is second to none. Recently, LEWCO used its expertise to design and manufacture two continuous process heating cells equipped with ovens, conveyors, and cooling zones. The 800°F ovens are used to cure polyethylene foam contained in aluminum molds. LEWCO engineers developed each oven …