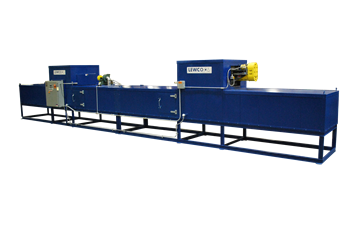

Custom High-Performance Drum Oven for Petrochemical Company

LEWCO, Inc. recently manufactured a custom High-Performance Drum Oven for a petrochemical company in Thailand. The oven is steam heated and is rated for a maximum operating temperature of 250°F. The oven is specifically designed to heat (4) 55 gallon drums and features a rear mounted steam heater box with a high efficiency circulating fan …

Read More “Custom High-Performance Drum Oven for Petrochemical Company”